Dry ice blasting is a game-changer in the industrial world, bringing efficiency and eco-friendliness to the forefront. This cool technique uses dry ice pellets—yes, the solid form of carbon dioxide; by shot at high speeds to clean surfaces without leaving any messy residue behind.

But before we dive into the details of its top applications, such as zapping away oil and grease stains, stripping paint, and smoothing out plastic, let’s break down what dry ice blasting is all about.

What’s Dry Ice Blasting All About?

Imagine blasting dry ice pellets at lightning speed with compressed air. When these pellets hit the surface, they immediately turn from solid to gas (sublimate), transferring almost no kinetic energy and causing minimal abrasion. This quick change absorbs a ton of heat from the surface, creating thermal shock that does the cleaning magic.

Ready to see how this nifty tech is changing the game? Let’s get into it!

1. Busting Oil and Grease Stains

Dealing with pesky oil and grease stains in industrial settings can be a real headache. Traditional cleaning methods? They’re not only time-consuming but often involve harsh chemicals that are no fun for the environment or the workers. Enter dry ice blasting—the ultimate cleaning superhero!

This cool technique makes cleaning complex machinery a breeze, cutting downtime and boosting efficiency. It uses tiny micro-explosions to lift and dislodge oil and grease from surfaces, keeping production areas sparkling clean. Say goodbye to stubborn stains and hello to a cleaner, greener workspace!

Benefits:

- Eco-Friendly: Unlike chemical cleaners, dry ice blasting leaves no secondary waste. The dry ice sublimates (turns from solid to gas) upon contact, leaving only the removed contaminants behind.

- Non-Abrasive: Dry ice pellets do not damage the underlying surface, preserving the integrity of machinery and equipment.

- Efficient: This method significantly reduces downtime, allowing for quicker cleaning and faster resumption of operations.

2. Paint Stripping

Getting rid of old paint is a must for many restoration and maintenance projects, but traditional methods like sanding or using chemical strippers can be a total drag, not to mention risky for your health. That’s where dry ice blasting comes to the rescue!

This awesome technique strips away paint without harming the surface underneath and doesn’t need any harsh chemical solvents. It’s efficient, safe, and makes your job a whole lot easier!

Benefits:

- Safe for Surfaces: Dry ice blasting can remove paint without scratching or wearing down the substrate, making it ideal for delicate surfaces like aircraft and automotive parts.

- No Toxic Chemicals: The process eliminates the need for hazardous chemical strippers, promoting a safer work environment and reducing disposal concerns.

- Speed and Precision: Dry ice blasting can quickly and accurately remove paint from complex geometries, enhancing productivity and quality of the final product.

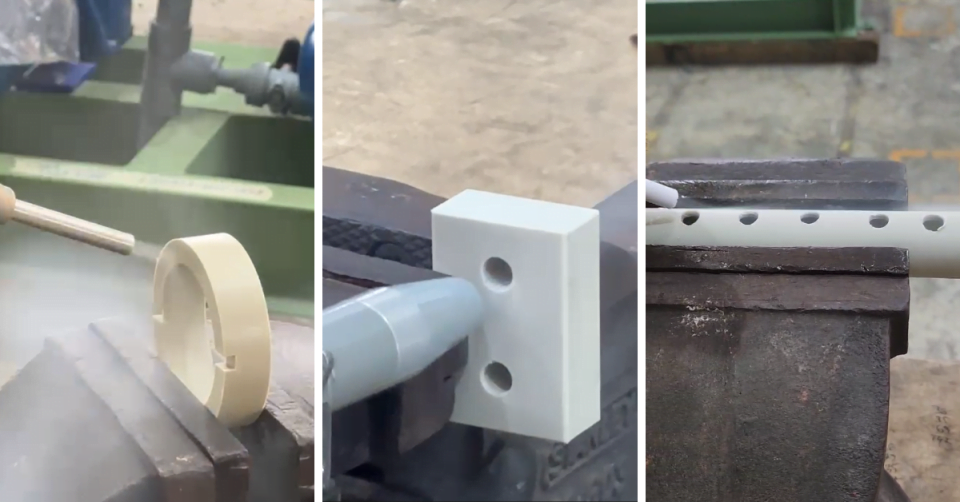

3. Plastic Deburring

In the world of manufacturing plastic components, dealing with burrs those pesky bits of excess material are a common challenge. Traditional deburring methods can be messy and not always precise. Enter dry ice blasting: a precise and efficient solution to the rescue!

Challenges of Manual and Machine Deburring

Manual deburring methods often fall short due to the risk of over-cutting and damaging the material, especially in hard-to-reach small holes and cavities. There’s also the potential risk of discoloring the plastic surface, not to mention the high labor costs involved.

On the other hand, machine deburring has its own set of drawbacks. It lacks the flexibility to handle varying scales, making it unable to effectively work on larger parts. Additionally, the precision equipment required comes with a hefty price tag and demands significant maintenance efforts. These limitations make finding the right deburring solution a critical task in manufacturing processes.

The Superior Solution for Plastic Deburring

By overcoming the challenges of manual and machine deburring, dry ice blasting ensures optimal results without damaging plastic surfaces. This cost-effective industrial process removes rough edges and imperfections from plastic parts by lifting away burrs and contaminants. Plus, it leaves no residue behind, making it both highly effective and environmentally friendly. Say goodbye to burrs and hello to perfectly smooth plastic parts!

Benefits:

- Precision: Dry ice blasting can target specific areas, removing burrs without damaging the surrounding material.

- Non-Abrasive: Unlike mechanical deburring methods, dry ice blasting does not wear down the plastic, ensuring a smooth finish.

- Cost-Effective: This method can reduce labor costs and increase throughput by streamlining the deburring process.

What Do We Offer to Meet Your Needs?

1. Pre-Sales Support

- Sample testing services

- Onsite demonstrations

- On-site training sessions

2. Technical Service Support

- Local ASCO-certified technicians

- Quick response times for repairs

3. Spare Parts Supply

- Common spare parts readily available

4. Rental Service

- Blasting machines available for short and long-term rental options

Conclusion

Dry ice blasting is transforming industrial cleaning and maintenance practices. Its capability to effectively eliminate oil and grease stains, strip paint, and deburr plastic components demonstrates its versatility and importance. Beyond its operational benefits, dry ice blasting stands out for its environmental friendliness and safety advantages, making it a preferred method in today’s industries.

Choosing dry ice blasting enables industries to achieve exceptional cleaning outcomes while advancing sustainability and operational efficiency. If you’re aiming to elevate your cleaning processes, now is the perfect moment to explore the potential of dry ice blasting.

For more information on sourcing dry ice blasting, including details on availability, pricing, and distribution options, click here to explore our comprehensive resources and support services.

Our Story

Our Story  Our Leader

Our Leader  Our Culture

Our Culture  Our Value

Our Value  Accreditation

Accreditation  Sustainability

Sustainability  Gasko Dry Ice Overview

Gasko Dry Ice Overview  Unique Celebrations with Dry Ice and Helium Gas

Unique Celebrations with Dry Ice and Helium Gas  Food Presentation

Food Presentation  ASCO Dry Ice Blasting

ASCO Dry Ice Blasting  Industry Solutions

Industry Solutions  Shipping and Transportation

Shipping and Transportation  Laboratory and Scientific Experiment

Laboratory and Scientific Experiment  Camping and Outing

Camping and Outing