We take pride in providing an exceptional experience for storing and delivering your perishable goods. As part of our commitment, we offer a comprehensive range of dry ice storage equipment with various sizes and capacities to cater to diverse requirements.

One of the key components of our storage equipment is Styrofoam, which is composed of about 98% air. This unique characteristic allows Styrofoam to trap air in countless small pockets, creating millions of tiny air bubbles within the foam.

Since air is a poor conductor of heat, Styrofoam efficiently prevents heat transfer. Unlike materials that conduct heat easily, air’s low mass limits its ability to store a significant amount of heat, resulting in minimal heat transfer through convection. Additionally, Styrofoam is not an effective conductor or radiator of heat, further blocking the flow of heat energy. Its ability to reduce both conduction and convection makes it one of the best existing insulators.

By utilizing Styrofoam in our storage equipment, we achieve excellent temperature control, insulation, and user-friendly interfaces, ensuring optimal storage conditions and extending the life of dry ice for your convenience and peace of mind.

Tips

Please Take a Pre-Caution Step!

Never handle Dry Ice with bare hands. We prioritize your safety, so please remember to use proper protective gear when handling dry ice.

With our user-friendly tools and safety tips, we’re here to make your dry ice experience as smooth and worry-free as possible. Let’s make the most of dry ice while keeping it fresh and safe for all your cooling needs!

Our Story

Our Story  Our Leader

Our Leader  Our Culture

Our Culture  Our Value

Our Value  Accreditation

Accreditation  Sustainability

Sustainability  Gasko Dry Ice Overview

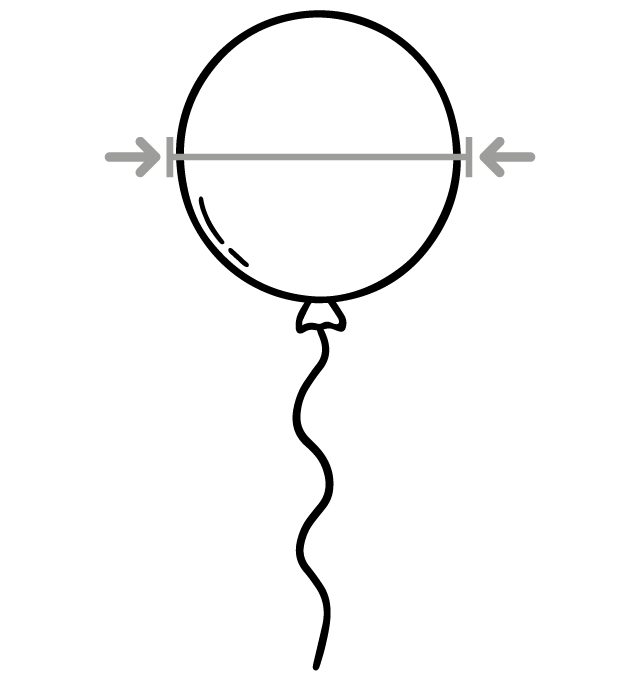

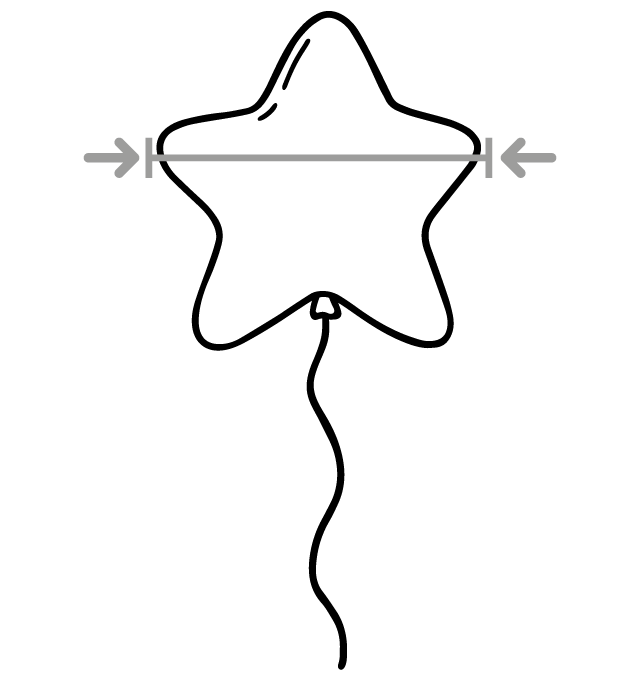

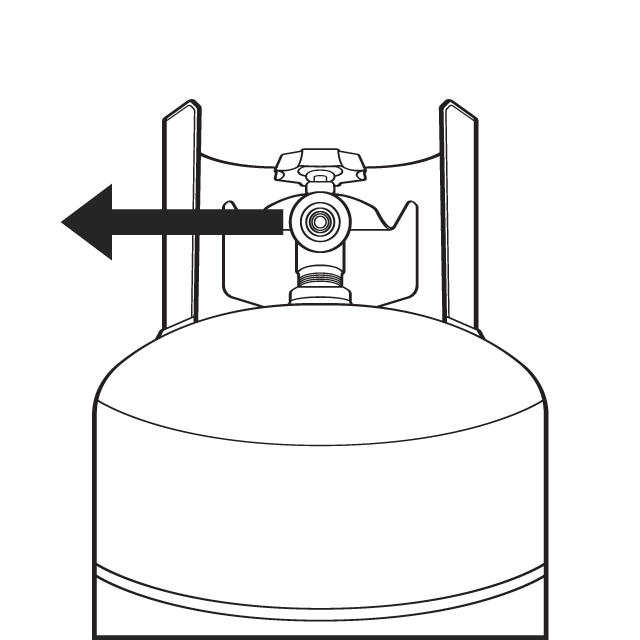

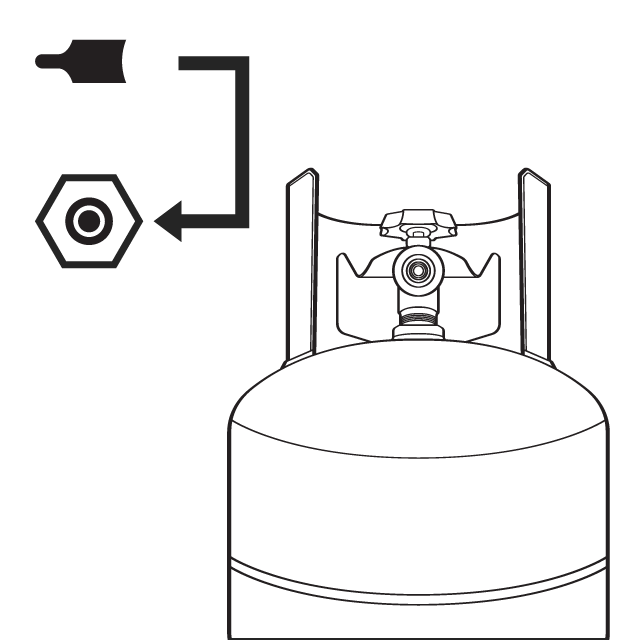

Gasko Dry Ice Overview  Unique Celebrations with Dry Ice and Helium Gas

Unique Celebrations with Dry Ice and Helium Gas  Food Presentation

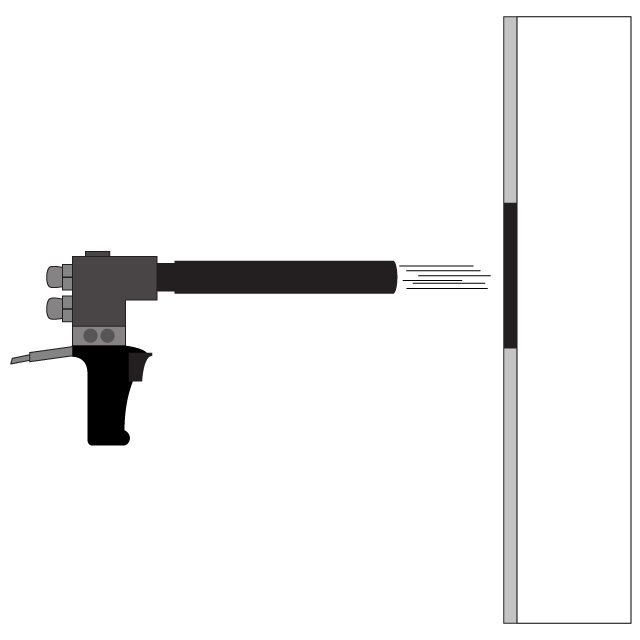

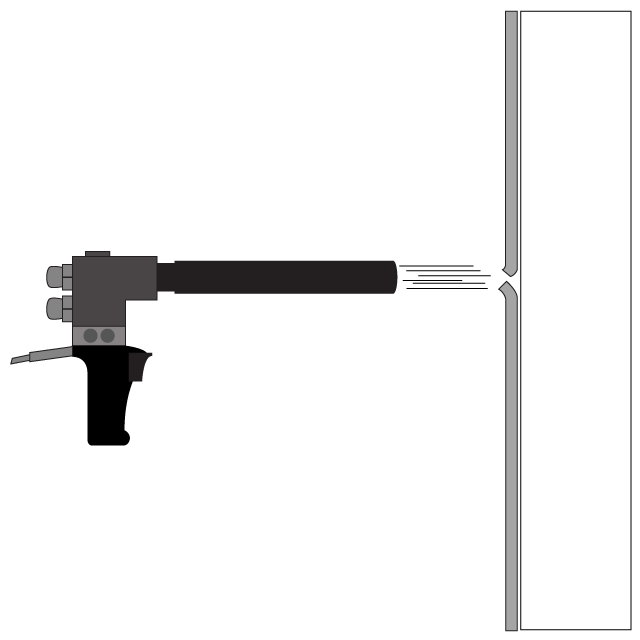

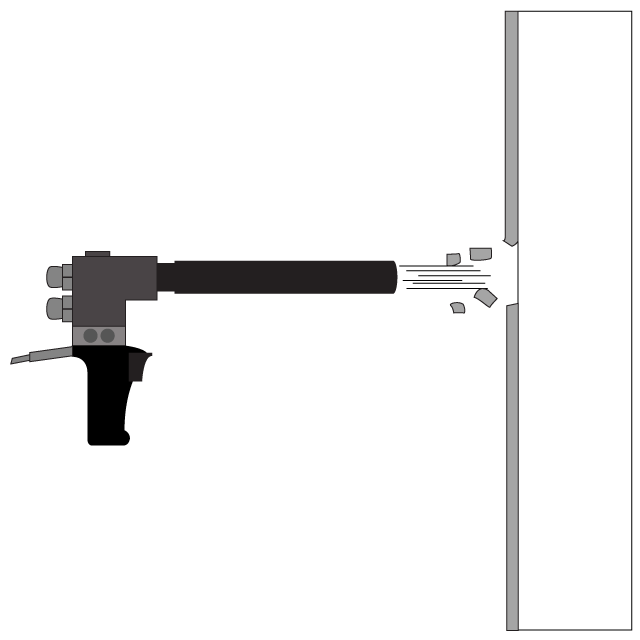

Food Presentation  ASCO Dry Ice Blasting

ASCO Dry Ice Blasting  Industry Solutions

Industry Solutions  Shipping and Transportation

Shipping and Transportation  Laboratory and Scientific Experiment

Laboratory and Scientific Experiment  Camping and Outing

Camping and Outing