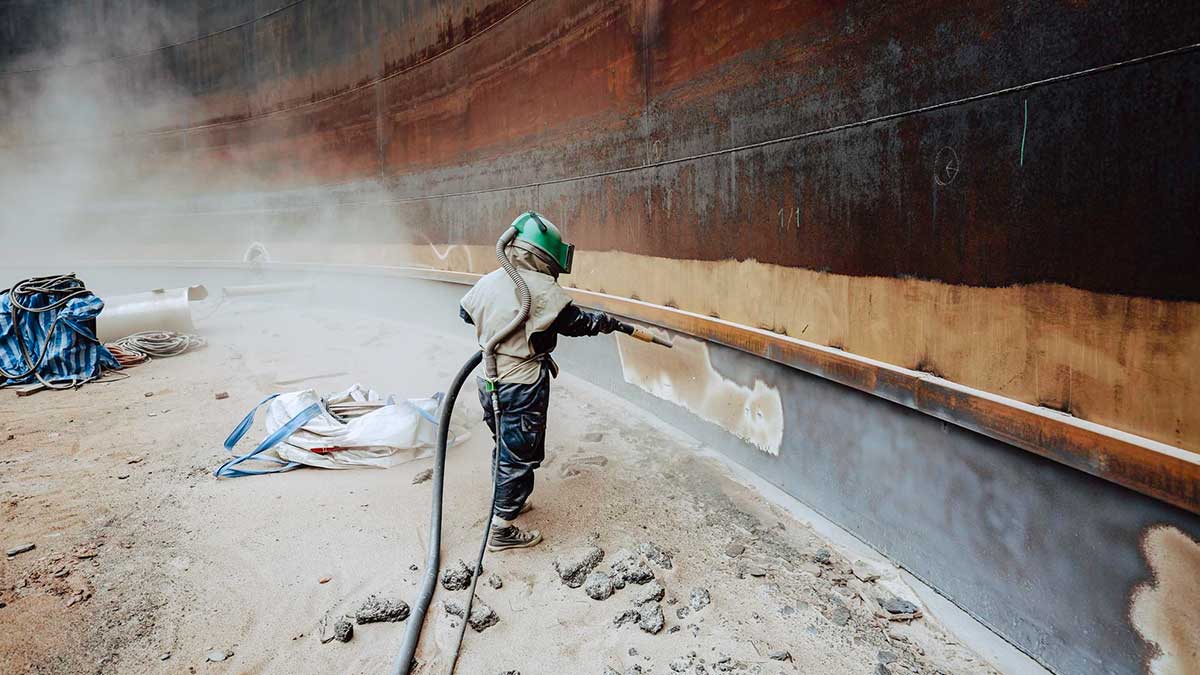

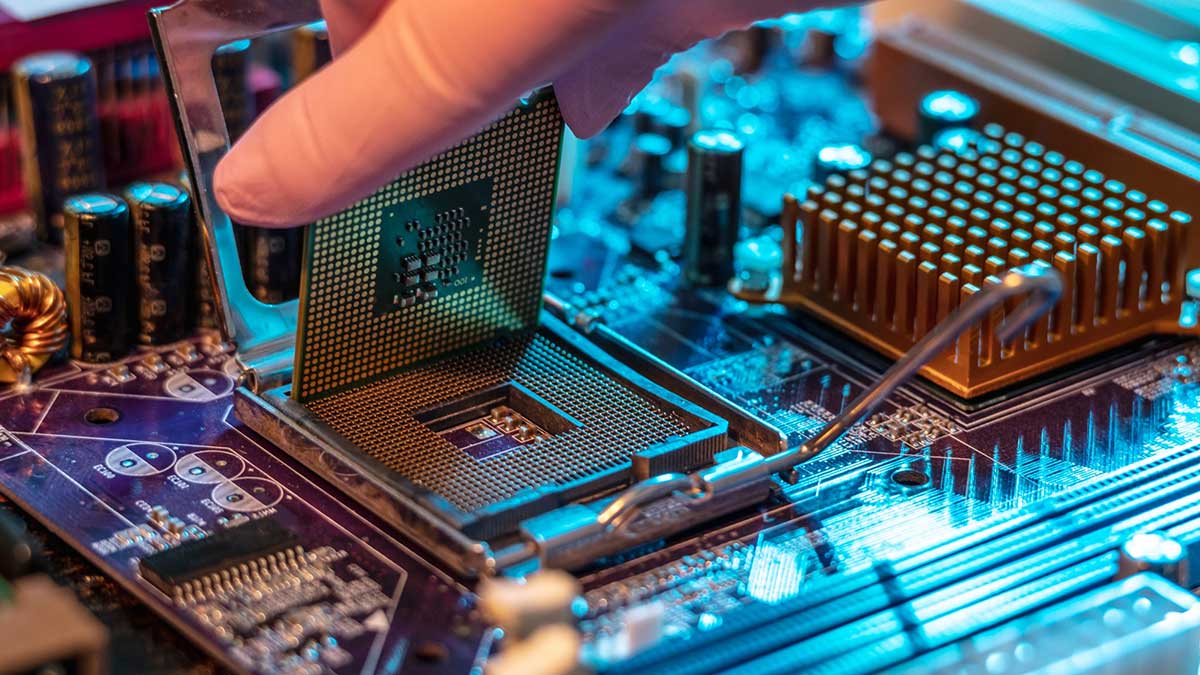

Our partnership with ASCO, a leading Swiss provider of dry ice blasting tech, positions us as pioneers in Southeast Asia for eco-friendly cleaning. We prioritize sustainability by using cutting-edge equipment that eliminates harmful chemicals, reducing environmental impact. Dry ice blasting is safe and effective for removing grease, adhesive, and paint from non-metal surfaces like plastic and aluminum. It’s ideal for sensitive areas like electric motors, food fryers, and aircraft engines. With our commitment to restoring surfaces and promoting responsible practices, we aim for a safer, greener future.

Our Story

Our Story  Our Leader

Our Leader  Our Culture

Our Culture  Our Value

Our Value  Accreditation

Accreditation  Sustainability

Sustainability  Gasko Dry Ice Overview

Gasko Dry Ice Overview  Unique Celebrations with Dry Ice and Helium Gas

Unique Celebrations with Dry Ice and Helium Gas  Food Presentation

Food Presentation  ASCO Dry Ice Blasting

ASCO Dry Ice Blasting  Industry Solutions

Industry Solutions  Shipping and Transportation

Shipping and Transportation  Laboratory and Scientific Experiment

Laboratory and Scientific Experiment  Camping and Outing

Camping and Outing